viAct

About viAct

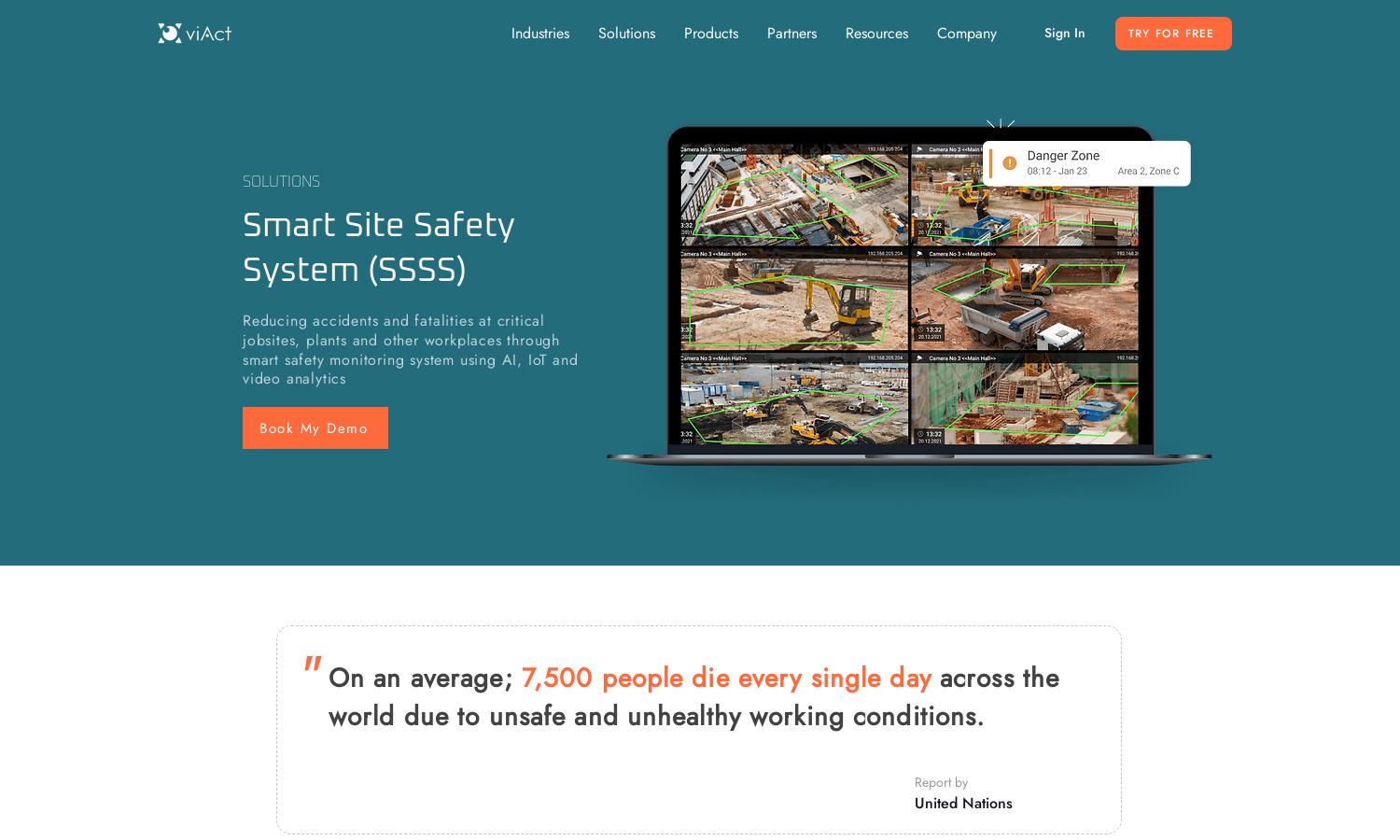

viAct is revolutionizing workplace safety with its Smart Site Safety System (SSSS). Targeted at construction, oil and gas, and manufacturing sectors, viAct utilizes AI, IoT, and video analytics to proactively identify and mitigate hazards, fostering a safer work environment and enhancing operational efficiency.

viAct offers tiered pricing plans, including a free 14-day trial of the Smart Site Safety System. Each plan provides increasing levels of features such as advanced monitoring and analytics. Upgrading allows users to access premium tools for enhanced safety protocols and operational control.

The user interface of viAct is designed for simplicity and efficiency. Its intuitive layout enables users to navigate smoothly through features, manage safety protocols, and access real-time data, ensuring a seamless experience and empowering users to maintain workplace safety effortlessly.

How viAct works

Users begin with a straightforward onboarding process by connecting existing IP cameras to viAct’s AI cloud system. From there, they can easily navigate the centralized management platform, monitoring safety performance and accessing various features such as permit-to-work systems and real-time alerts, all designed to enhance workplace safety with ease.

Key Features for viAct

AI-Powered Real-Time Monitoring

viAct's AI-Powered Real-Time Monitoring feature ensures continuous safety oversight at job sites. This innovative technology detects potential hazards, allowing workers to address risks promptly. By providing instant alerts, viAct assists users in maintaining compliance and enhancing worker safety effectively.

Digitized Permit-to-Work System

The Digitized Permit-to-Work System from viAct streamlines safety authorization processes through AI video analytics. It significantly reduces human error, enhances compliance, and speeds up approvals, ensuring that safety protocols are adhered to consistently and efficiently.

PPE Detection System

The PPE Detection System is a key feature of viAct, constantly monitoring worker compliance with safety gear requirements. This proactive measure helps to reduce workplace accidents by identifying non-compliance in real-time, thus ensuring the highest safety standards are maintained.

You may also like: